MareWint Project

new MAterials and REliability in offshore WINd Turbines technology

Research area: FP7-PEOPLE-2012-ITN Marie-Curie Action: “Initial Training Networks”

Project start date: [2012-10-01]

Project reference: 309395

http://www.marewint.eu/

PARTNERS

|

|||

MAREWINT WP4 – Reliability and Predictive Maintenance

MAREWINT research program activities overview

Reliability Prediction for a 10MW Offshore Wind Turbine

Reliability Block Diagram (RBD) for a 10MW Offshore Wind Turbine

Failure Mode and Effects Analysis (FMEA)

Reliability Centered Maintenance (RCM)

MareWint Project

One of the strategic objectives of the industrial initiative of the SET Plan on wind energy is to reduce cost of energy by improving reliability of wind turbines and their components and optimizing operation and maintenance (O&M) strategies. Increasing reliability and optimizing O&M have a direct impact on the availability of wind turbines and thus reduce cost and increase energy output. This strategy considerably contributes to making wind energy fully competitive. This is particularly evident in the offshore sector, where O&M represents a high percentage of total costs.

MARE-WINT will contribute to the achievement of this goal by proving training in the context of doctoral programmes for 14 researchers in multi-disciplinary area of future generation of Offshore Wind Turbines (OWT) engineering focusing on issues having a major impact on the mechanical loading of OWT and which are still not sufficiently understood.

OWT is a complex energy conversion fluid flow machine which entails coupled hydro-aero-mechanical issues. To design, built and operate a reliable OWT knowledge from disciplines like mechanical engineering, material science, metrology, fluid mechanics, condition monitoring, and computer simulation need to be combined. It is the ambition of MARE-WINT network to bring together specific partners capabilities and know-how to realize tailored training trajectories, focusing on increased reliability OWT design.

Balanced industry-academia network consortium includes 6 Universities, 7 Research Institutes, 4 SMEs and 7 Large Industry Partners.

The participation of 13 private sector Partners active in off-shore developments is essential to achieving the full impact of the project. Industrial partners are involved in hosting, training and defining the training needs of the researchers. Strong involvement of the industry will give PhD students the widest possible employment prospects. There are 4 Industrial PhD programmes identified within MARE-WINT project.

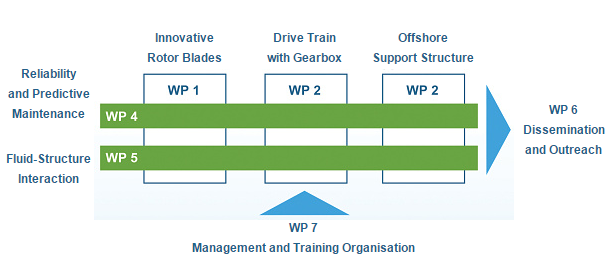

For a management of the ITN project and training organisation dedicated WP7 was defined:

- WP1 – Innovative Rotor Blades

- WP2 – Drive Train with Gearbox

- WP3 – Offshore Support Structure

- WP4 – Reliability and Predictive Maintenance

- WP5 – Fluid-Structure Interaction

- WP6 – Dissemination and Outreach

- WP7 – Management and Trainin

Relex Italia is participating extensively in WP4 – Reliability and Predictive Maintenance.

MAREWINT WP4 – Reliability and Predictive Maintenance

‘Reliability Model for an OWT will be developed and used to evaluate the main reliability and availability characteristics of the OWT considering the introduction of new materials as optical fibres for health monitoring and the new offshore stresses scenario. For the first time in the European Wind Energy Sector, we will propose to use an RCM (Reliability Centered Maintenance) approach to detect actual failures, isolate these failures and assign them to a specific component, determine the residual life of components, define and schedule maintenance actions in an optimum sequence and, finally, support maintenance technicians and managers to make the most adequate decisions concerning maintenance policies’

Relex Italia SRL (Department of Reliability and Safety) is participating to the MAREWINT European Project . Relex Italia work concentrated on the development of a Reliability Assessment Model and the Definition of a RCM (Reliability Centered Maintenance) approach for an Offshore Wind Turbine.

Overview of the key research objectives

As we made for Reliawind Project, we developed a Reliability Model for an offshore Wind Turbine. This Model has been used to evaluate the main Reliability and Availability characteristics of the Wind Turbines considering the introduction of new Materials as optical fibres and piezoelectric transducers for health monitoring and the new offshore stresses scenario. For the first time in the European Wind Energy Sector, we will use an RCM (Reliability Centered Maintenance) approach to study actual failures modes of Offshore Wind Turbines, isolate these failures and assign them to a specific component, determine the residual life of components, experiencing impending failures, define maintenance actions to be taken, schedule these actions in an optimum sequence and, finally, support maintenance technicians and managers to make the most adequate decisions concerning maintenance policies.

RCM will help to identify policies that must be implemented to preserve the function of the Offshore Turbine in its operating context. Thus, we will focus on how to preserve the function of the system, not just maintaining the operation of the equipment. By focusing on system functions rather than equipment operation, a myriad of possibilities that extend beyond just maintenance procedures will be explored which may be overlooked with a traditional maintenance analysis.

Introducing these System Reliability Engineering best practices, Relex Italia is going to provide the European Wind Industrial community with basic knowledge on methodologies successfully experienced from other industrial sectors (e.g. Aerospace and Defence).

This will be done with the aim to:

- Maximize overall Wind Turbine performance

- Avoid Abnormal Incidents

- Reduce lost profit opportunities

- Reduce maintenance budget

- Improve productivity

- Improve Mechanical integrity

- Reduce the amount of capital investment needed.

- Reduce liability insurance costs

- improve Safety

- Ensure no surprises for maintenance and operations

- Provide common view of Wind Turbine health by bringing together data from multiple sources including multiple predictive technology.

MAREWINT project research program activities overview

In the MAREWINT Project we extended the Reliawind WTG model to an Offshore Wind Turbine.

We transferred all the documentation and software models realized with Reliawind and we went through a more detailed training program with the aim to deriving Failure Rate Adjustment factors to convert the Predictions made for onshore 5MW turbine into the new model for offshore 10 MW wind turbine.

A new component database for the offshore environment including updated failure rate and Mean Time To Repair characteristics has been created that has been used for the Reliability Assessment of the offshore turbine. The analysis of the Off-shore Wind Turbine (OWT) has been carried out using different reliability techniques and the software tool ‘PTC Windchill Quality Solutions’.

As first step, the reliability prediction analysis has been performed and based on these results a functional model has been created from which the Reliability Block Diagram analysis (both with Analytical and with Monte Carlo simulation approach) and the FMECA have been performed, starting from line replaceable unit (LRU) level up to system level.

The results of these two Reliability Analysis will be used to complete an RCM Process to optimize operation and maintenance of two wind turbine subsystems.

Reliability Prediction for a 10MW Offshore Wind Turbine

The reliability prediction analysis is used to obtain the system failure rates by gathering information regarding components (like stress data, quality information, temperature, and environment factors), and performing a calculation based on standard equations. The reliability analysis is based on the assumption of statistically based failure rates, which are constant over the useful life of the individual components of the unit ). The assembly model used for the Prediction is a series model (failure of any component causes an assembly failure).

In this case all failure rate data have been taken from the study of the 5 MW On-shore wind turbine analyzed in the ‘RELIAWIND project’. For this reason the following equation has been applied to each components in order to convert the value of failure rate for a 5 MW On-shore WT into failure rate for a 10 MW Off-shore WT.

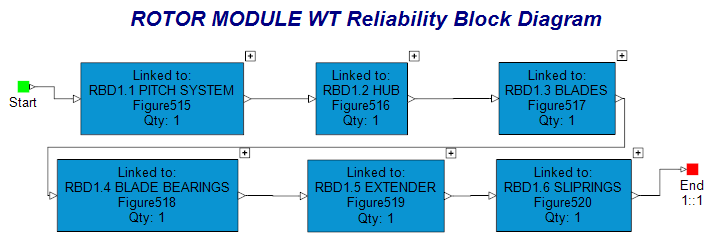

Reliability Block Diagram (RBD) for a 10MW Offshore Wind Turbine

Because reliability predictions assume that all components in a system are in series, they cannot be used to analyze a system with redundant components. RBDs are used to evaluate the reliability of systems that are complex in their configurations.

An RBD (Reliability Block Diagram) is a visual representation of the portions of the system to be modeled. RBDs also provide an efficient and effective way to compare various configurations to find the best overall system design. The goal of reliability block diagrams is the determination of almost all reliability and maintainability metrics of a complete system, like Reliability, Availability, Failure rate, MTTR (mean time to repair).

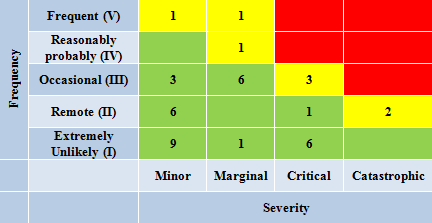

Failure Mode and Effects Analysis (FMEA)

The main target of the analysis is to discover the weakest parts of the Wind Turbine, understanding their failure modes, the effects they cause and then improve their availability introducing possible redundancies or design changes and updating their preventive maintenance.

Other objectives that are possible to achieve through this analysis are:

- Anticipate the most important problems

- Prevent them from occurring

- Minimize their consequences as cost effectively as possible

- Give technical information to maintenance personnel about failures that might come out during system life

- Compare results with previous maintenance reports and then update again the analysis

- Provide necessary information to create a cost/benefit analysis

- Provide those modes that need preventive maintenance in a risk priority order

Reliability Centered Maintenance (RCM)

According with NAVAIR 00-25-403 (Management Manual: Guidelines for the Naval Aviation Reliability Centered Maintenance Process) RCM process has been divided into four major steps as:

- Planning Phase

- Performing the Analysis

- Implementation

- Sustain the Analysis

Planning Phase

- Establish RCM team

- Determine what to analyze

- Determine the RCM Analysis approach

- Establish priority for items

- Determine the review process

- Develop RCM Program Plan and Ground Rules & Assumptions

Performing the analysis

- Kick off meeting

- Gather the data

- Hardware partitioning

- Significant Function Identification

- Failure Modes, Effects and Criticality Analysis (FMECA) Development:

- FMEA Analysis:

- Define the function

- Define the functional failure

- Failure Mode

- Failure Effects

- CA Analysis

- Severity of the Failure

- Failure Frequency

- Function preservation evaluation

- RCM Decision Logic

- Failure consequences evaluation

- Task Evaluation

- Function preservation selection

- Task Selection

- Task Interval Calculation

Implementation

- Task Implementation

- Package PM tasks at the correct interval

- Implement One Time Changes

- Define a set of recommendations for a series of discrete maintenance tasks.

- Combining those discrete tasks into an efficient, effective, and executable maintenance program.

- Combine Concurrent tasks into a set of “work packages”

- Define and Implement AE (Age Exploration) Tasks

Sustaining the Analysis

- The initial analysis may need update over time.

- Incorrect assumptions on initial analysis

- Hardware changes

- Unexpected failures

- Operating environment changes